Why Omega EMS

Redefining New Product Introduction

Pitfalls of Traditional NPI

- Materials Management

- Procedure & Policy

- Procedural “red tape”

The Omega EMS Difference

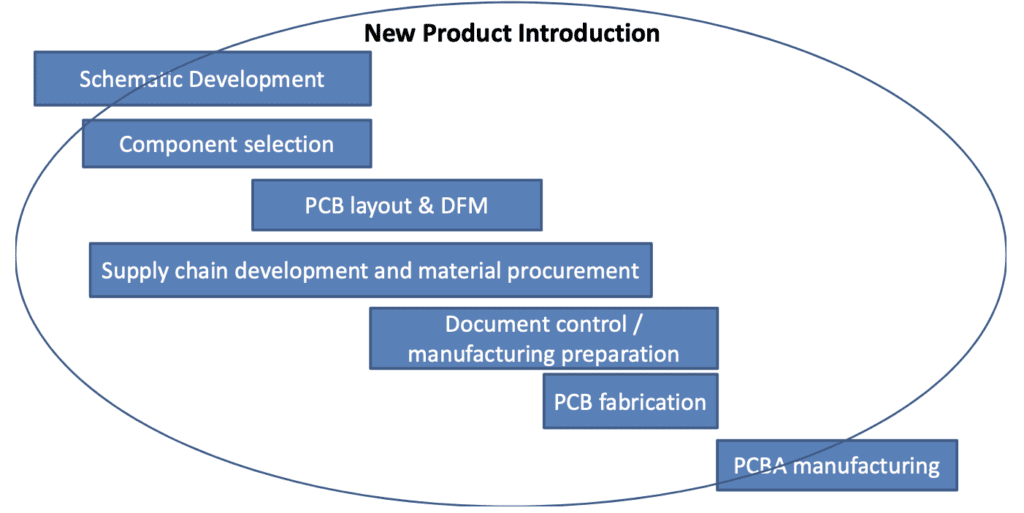

At Omega, we believe New Product Introduction (NPI) should go beyond the typical approach of quick-turn prototype manufacturing. Our comprehensive NPI support bridges all activities related to creating a new product – by defining and managing the “right EMS solution” via trusted supplier partners and experienced management teams.

Our team will oversee and manage all parties to ensure all activities are inline with the project critical path; Using a Sr. level PM as the single point of contact; “In parallel “project management coordinates between internal layout, material procurement, PCB fabrication and manufacturing preparation to ensure all parties are on schedule.

Experienced from Concept to Production

There are many common NPI pitfalls that can not only cause a major impact to your product development schedule but also cost you additional time and money. Some of these items may include:

- Lack of a realistic and clearly defined schedule

- Lack of schedule tracking and communication: accountability for all parties

- Unrealistic production ramp: usually results in the selection of the wrong manufacturing partner

- Small EMS players have process excellence but lack sophistication in Materials Management / Procedure & Policy

- Large EMS solutions lack flexibility and interest in smaller revenue streams creating procedural “red tape”

- Proper negotiations and pricing registration: timing is crucial

- Failure to determine test strategy / philosophy prior to layout completion

- Basic document control enforcement: part number, revision and data control

- Not pipelining material appropriately at the right time

- Not understanding the impact of ECO and design changes for product in WIP

- Building too few / too many prototypes

- Trying to transition to low cost regions prior to design stabilization

Omega EMS leverages it’s extensive project management experience to identify the critical path to your projects success and proactively prepare and plan for any potential roadblocks to ensure your schedule is met.

A Commitment to Quality

At OmegaEMS, we make sure our customers get the best in Printed Circuit Board and System Integrated Products. We are committed to ensuring that all products meet safety regulations while providing reliability, efficacy and outstanding value for money — always on time! Furthermore, we strive towards excellence by fostering a culture of quality awareness across our organization. It’s this combination of product dependability & customer satisfaction that makes us stand out from the rest!